Industrial IoT and PLCs

Industrial IoT is growing rapidly. However, traditional PLCs don’t offer sufficient flexibility and connectivity as required by engineers. Customizing solutions to achieve the required flexibility and connectivity is costly and time-consuming. More so, very few engineers have the experience required to develop a functional -based embedded solution.

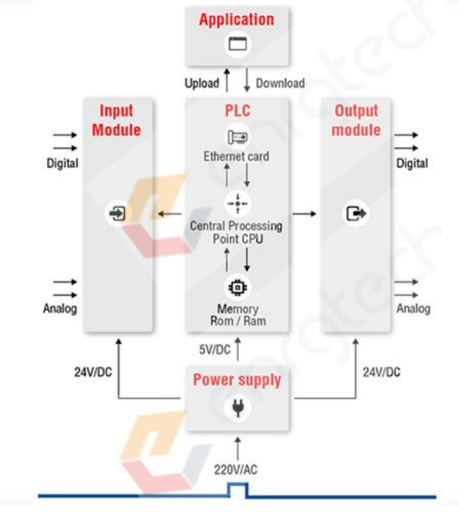

Programmable Logic Controllers

- A PLC is a programmable controller that has been ruggedized and tailored to perform a specific process in an industrial application. The process differs from industry to industry. A PLC architecture incorporates the following;

- A central processing unit

- Digital and analogue input and outputs

- Power supplies

- Logic application

Wireless PLC

To build a Custom wireless PLC one would require the following;

- A CPU

- Input/ Output signal conditioning

- A Wi-Fi module

One can build these components from scratch but that would be time-consuming. It is easier to utilize the existing ecosystems. One such ecosystem is STM’s developer pack. The developer pack incorporates a CPU, input/output signal conditioning, and a Wi-Fi module.

The STM32 developer pack

CPU

The is a 32-bit Arm Cortex- M4 processor. It runs at 84MHz and has 513 Mbs of space for app and 96Kb of RAM. This CPU is provided for in the Nucleo-401RE evaluation board. This board also includes Arduino headers that interfaces with other hardware alongside an ST-Link for programming the embedded software.

Signal conditioning board

STM’s X-Nucleo-PLC01A1 has 8 conditioned inputs through CLT01-38SQ7 which provides digital protection for the PLC through limiting the current taken up by input pin. There are also 8 outputs that have been conditioned using monolithic 8-channel driver which provides 8 solid state relays on-chip with each driving up to 0.7 amps. The board also comes with an LED indicator that displays the state for each input and output. It also has 3 alarm lights to signal board faults. The board communicates with the CPU through the SPI communication link.

Wi-Fi module

The is 802.11 b/g/n compliant. This Wi-Fi expansion module can be used to create an IoT connected PLC wireless chip. The module is FCC, IC and CE certified and has an integrated antenna.

PLC software

To set up PLC, there are several pieces of software needed. They include:

- PLC embedded software

- Embedded compiler

- Ladder logic application

STM offers a PLC embedded software, FP_IND_PLCWIFI1, and is available for download from the STM website. This software has all the software required for to run and has several preset configurations depending on the required hardware stacks. The software comes with three projects set for and ready for the STM, IAR and Keil MDK workbenches. Once downloaded, the application can be compiled before being downloaded to the PLC using a standard USB connection.

You May Like:

Summary

provides numerous ecosystems that make it easy to build custom Wireless PLC. The ecosystem enables a developer to develop a PLC software fast. The software can be modified and customized easily to achieve numerous goals and execute several processes. With this ecosystem, engineers can achieve unmatched sufficient flexibility and connectivity that they would require to develop various industrial solutions.

0 Comments